Fermentation has become a major focus of improvement in my brewing efforts. After all, why waste a batch of beer you spend hours brewing only to slack off on the cold side of the whole process?

I mentioned this in a previous blog post, but the biggest improvement in my homebrew came from proper pitching temps and temperature-controlled fermentation! Actively fermenting beer can be 10 degrees higher in the fermentation vessel than the ambient temperature of the room. So if your brewhouse is 70°F your beer could be 80°F during active fermentation. Yeast produces more esters and off-flavors at higher temperatures, therefore a cooler fermentation is going to produce greatly improved results.

In an attempt to gain better control over my fermentation capabilities, I upgraded from a standard plastic bucket to the stainless steel 7.5 gallon Anvil Bucket ($129) and Anvil Cooling System ($129). I’m going to dive into both components below.

Product Overview

My Anvil Bucket Fermenter has a 7.5-gallon capacity and is adequate for 6-6.5 gallon batches. The fermenter features a tilting racking arm, a slightly coned bottom, a domed lid, etched gallon markings, and a spigot for easy sampling or transfers. Overall the finish is really smooth and contains no imperfections. It feels very well built, sturdy, and looks really nice in any brewery. It’s easy to clean, feels a lot fresher to me, and I trust there will be a greatly reduced risk of contamination over the plastic counterpart.

The fermenter lid clamps on with 4 clips ensuring a nice tight seal. I really like this feature as it is easy to pop open for any additions without shaking the entire fermenter. The domed bottom is great for helping to separate the trub from the racking arm, giving you cleaner draining ability with less risk of clogging or transferring junk. The spigot is also really handy for quick samples or transfers to a keg without the need for an auto-siphon. I found this handy for filling my hydrometer tube for gravity readings! No need to open the lid and expose your beer.

Lastly, the racking arm can be rotated by turning the outside spigot left or right. You can also adjust it to pull from any direction if you’d rather leave the last inch or so of beer in the fermenter. This is night and day over the standard bucket spigot.

It’s worth noting that the Anvil fermenter and the cooling system are both sold separately. You can also buy this fermenter in a smaller 4-gallon version as well.

The Cooling System

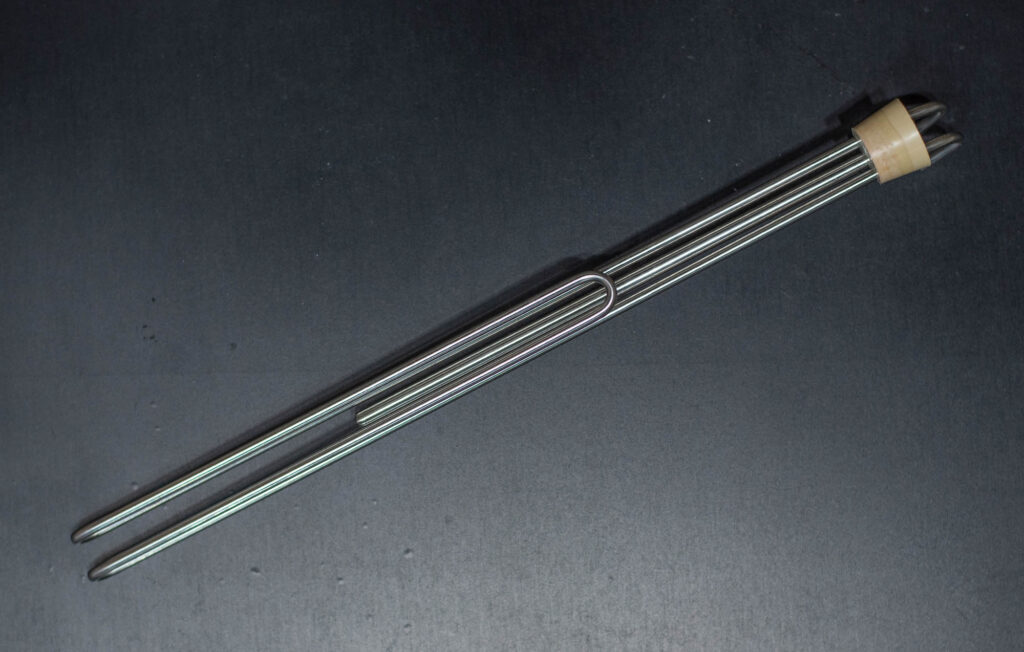

The cooling system comes with a pump, neoprene jacket, Anvil temp controller, long stainless steel cooling coil, a thermowell, and a special no. 7 rubber stopper. The coils and thermowell pass through the stopper and extend into the fermenter. The thermowell sits about halfway down the bucket and the coils reach a few inches from the bottom of the vessel.

How Does it Work?

The digital thermometer probe fits into the thermowell and will give you a digital temp reading at the very center of the fermenter. You set your desired fermentation temp on the controller and plug the supplied pump into the controller. If the temperature of the vessel raises even 1 degree (you can change the variance on the controller), it will activate the pump and cycle cold water (from a cooler) through the coils, bringing down the temp pretty quickly.

Anvil fermenter with water supply below in cooler.

You’ll need a cooler full of ice water as the water supply for the cooling system. This is absolutely the most inefficient part of the entire process. The water often returns to room temp every 6-8 hours and renders your cooling efforts useless. You will need to swap out fresh ice or ice packs daily to ensure your water supply remains cold.

The cooling system has been critical in maintaining my fermentation temps down to the degree. I use an Inkbird digital temperature controller to easily ferment in the 64°F-68°F range. The newly supplied thermostat with the system also works just as well. You could absolutely push this fermenter colder into the 50’s assuming you keep replenishing the cold water supply.

Overall this setup is one of the more budget-friendly solutions to control fermentation temps precisely. Sure you can improvise with draping your fermenter with a cold or frozen towel or keep your fermenter in the bathtub but you certainly won’t get this level of automated control. I would absolutely recommend this fermenter for anyone looking to get started with more control over their fermenting environment.

Can I Use The Cooling System in A Glass Carboy?

You absolutely can. Just note the supplied stopper is a no. 7 stopper so you will need a carboy with a no 7. mouth. Anvil makes a carboy version of the cooling system as well.

Other Ways to Keep The Water Supply Cold?

If you have an extra mini fridge with a freezer on hand you could drill holes in it for the tubing to pass through and create a closed-loop glycol system with a glycol reservoir inside. A 50-50 mix of glycol and water has a freezing point of -35°F. The solution won’t freeze in the freezer and will deliver colder liquid through your cooling coil—and most importantly the liquid will STAY cool.

It won’t be ultra-efficient like a true glycol setup but it would be better than ice water. You would still need another means to cold crash, however. There are many well-documented posts on Homebrewtalk that illustrate what I’m talking about.

Final Thoughts

Overall, the Anvil system is a really great product and a stellar way to really improve your homebrew without breaking the bank. The fermenter is well made, easy to clean, and can be set up for closed transfers with some inexpensive modifications. I would definitely recommend the stainless Anvil Bucket and Anvil Cooling System if you are looking to move to stainless and step up your fermentation control.

The total cost of the package is about $260 all in, making it a high-value buy in comparison to the competition. If you’re on a tighter budget, I would still grab the bucket NOW and upgrade to the cooling system later on when you can.

My only regret is that I wish I invested in a system like this a lot sooner. It certainly would have saved me a tremendous amount of batches that suffered from hot fermentation. Overall, this system just makes fermentation that much easier. I love the design and would have to agree it’s a major upgrade over a plastic bucket in so many ways.